289 Fastback Suspension Overhaul

This '68 Mustang just got running again. Turning? Now that's a different story...

"All we gotta do is bleed the brakes..."

My late grandmother’s ‘68 Mustang spent most of the last 20 years outdoors behind the Elliott family home. With several valley oak trees dotting our yard, there was plenty of mud, pollen and detritus around for it to gain its share of patina. In 2014, my father and I hauled some tools out back and began working on it together. At the time,we thought the only obstacle standing between us and a cruise in this all-original family heirloom was a spongy brake pedal.

"All we gotta do is bleed the brakes" my father boldly declared that summer. Neither of us understood just how much of an oversimplification that inaccurate sentence was. To this day we still use it as a common figure of speech around the shop. It’s a phrase used to affirm that most tasks are far more easily described than they are completed. A way of flagging that the effort required for most automotive work is easily underestimated.

Jokes aside, the Mustang’s brakes were a good place to start. Judging from its then-equipped tires (which were stamped out in early 2009), this Mustang had been out of use and motionless for at least 5 years. The brake fluid was surely scores older.

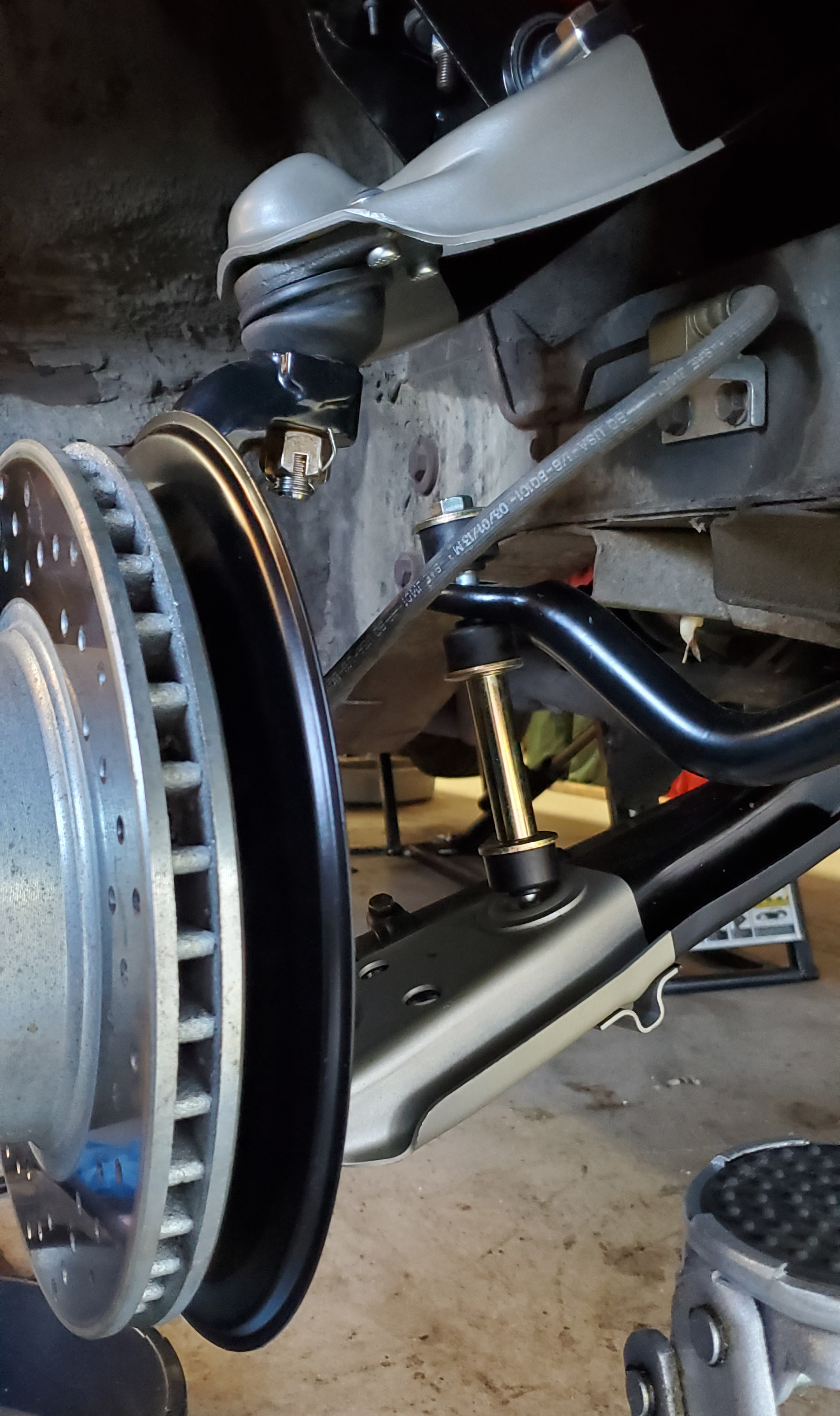

Preserving the car’s apparent originality is important to me and my father. However, we agree that modest upgrades to wearable are totally on the table. We started replacing the calipers and installing new drilled rotors up front. We like the vintage racing aesthetic they have, even though slotted rotors are more effective. Moving to the rear (drum) brakes, we had a run-in with one of the car’s large, new arachnid tenants. Following its eviction from the space between the drum and the wheel, new brake shoes were installed on both sides of the car. Getting the stiff little retainer springs which hold the shoes to stay in place can be diabolically difficult. Having a buddy to help you muscle everything into place is beyond valuable for this job.

After pumping several quarts of DOT-4 through the system, we determined that a new brake booster and master cylinder were necessary to keep the system strong and airtight. (These were the first of many critical unforeseen jobs which held up our build, in addition to simply "bleeding the brakes"). Once we were convinced the car would stop, we decided to leave the rest of the suspension for another time. It would remain in the above state until the Spring of 2020.

Exploring Ancient Grease

In March of 2020, the COVID-19 pandemic got into full-swing and our lives shut down. If there was a silver lining for me, it was that my father and I found ourselves with newfound time for automotive endeavors. It had been five or six years since we had spent quality time with the mustang, so we seized the opportunity to throw the ‘68 up onto our Quick Jacks. It was a wonderful chance for us to give the car some attention and spend some time bonding together. Not to mention that it kept us away from the news and our phones.

By now the car had already been turned over to a local shop. They were able to get the motor up and running correctly--or at least as good as can be given what we have. On the drive home, the 289ci V8 sounded healthy. However, the handling indicated that all the bushings were half powderized. Once the car was up on the Quick Jack, a quick inspection of the front suspension confirmed what the car’s feedback alleged.

My father lived in the Sunset district of San Francisco for a while, and this car was his daily driver. The salty sea air beat the shit out of anything that wasn’t 100% coated, and most of the suspension was not spared. Most of the metal below the car’s beltline was quite corroded. Rather than attempting to restore the original tie rods and control arms, we opted for readily available and decent quality replacement parts online.

We used mostly Scott Drake parts, ordered from places like National Parts Depot, CJ Pony Parts, and West Coast Classic Cougar. While the parts were shipping out, my dad and I consulted Haynes manuals and YouTube tutorials on classic Ford suspension rebuilds. We began to disassemble the front suspension, and promptly discovered that several of the car’s nuts and bolts were rusted together with strength that would embarrass some welds. A combination of WD-40, Brākleen, blowtorches, and large hammers managed to break even the toughest fasteners free in the end.

Taking off the spindles, which are the primary point of attachment for the wheels up front, was a particularly difficult part of our teardown. It’s very easy to unbolt things in the ‘wrong’ order, giving you little-to-no mechanical support to brace against while undoing rusted-over nuts. The fasteners that hold the lower control arm to the spindle can’t have any torque applied to them unless the spindle is held firmly in place. The car’s geometry can do this for you on one side. On the other side the geometry is mirrored. For this reason, removing the spindles before taking off the tie rods is crucial if you want to save yourself some excess work.

Freeing up the strut rods was challenging as well, since their studs are exposed to every puddle that comes near the car’s nose. The nuts holding the strut rod bushings in place are an unusual size, I think somewhere between 1+1/16" and 1+1/8", which is larger than any wrench I have. Adjustable wrenches will have to do, unless you’d like to buy some specialty tooling.

Once the new control arms, sway bar, shocks, springs, and strut rods were in place and secured, it was time for the tires to go back on. After placing the front wheels back on and lowering the car down, each of the wheels had a completely different tow angle, and both were rocking a ton of positive camber. The car was running a little rough, but I assumed it was simply due to cold weather. After screeching its way down the road to the nearest Big O Tires, the Mustang was finally ready and present to be aligned. The owner-operator of the place was there to help us out, and to provide some veteran hotrod wisdom...

Since the car had been lifted on the Quick Jack for weeks, neither my dad nor I had noticed the car's stance until we were at the tire shop. The car's front end was pitched way up, pointing skyward a few degrees more than it should. This was, as Ed from Big O noted, due to the half-century old (leaf) springs in the rear. They were quite tired, and couldn't help but work in conjunction with the brand new front springs to give the car a gasser's rake. The adjustable red Konis were probably also set too stiffly, as a firm press on the car's fenders wasn't met with any compression from the suspension. (In fact, the tires had plenty more give than any of the car's geometry).

The drive home was uneventful, but the motor still didn't seem too happy. Rather, it sounded like it was running on seven cylinders. After some close inspection, the cause was determined to be a spark plug that was missing its wire. I can recall that, while working on the front shocks and springs, I did remove the wire so I could access the fender apron with more ease. (Lesson learned!) Once the wire was back on it's plug, the idle cleared right up and the Mustang was finally roadworthy once more!